Ecoregion Bergamo, Italy

In the Bergamo ecoregion, several assets are described below :

Localisation

Cartiera CA-MA

The plant has a productive and warehouse area of 20.000 sqm and it can produce 140 tons of cardboard a day. A 2 MW cogenerator is installed at the plant to produce steam and electricity for 5,500 hours/year; in part, the company also recovers hot water from this system at a temperature of around 70°C, but there is still a recoverable potential of around 20%, equal to around 500 MWh per month. The heat recovered, both in terms of steam and hot water, is measured by special heat meters. The production site is bordered by an artisan area and by the village of Lallio, where in a range of 500-800m of pipeline there are schools and other public buildings.

Yes, we believe in energy cooperation

Localisation

TURBODEN

Turboden, a Mitsubishi Heavy Industries company and a LE2C’s member, is an Italian firm and a global leader in the design, manufacture, and maintenance of Organic Rankine Cycle (ORC) systems, highly suitable for distributed generation. ORC systems can generate electric and thermal power exploiting multiple sources, such as renewables (biomass, geothermal energy, solar energy), traditional fuels and waste heat from industrial processes, waste incinerators, engines or gas turbines.

Localisation

A2A Calore&Servizi

The objectives

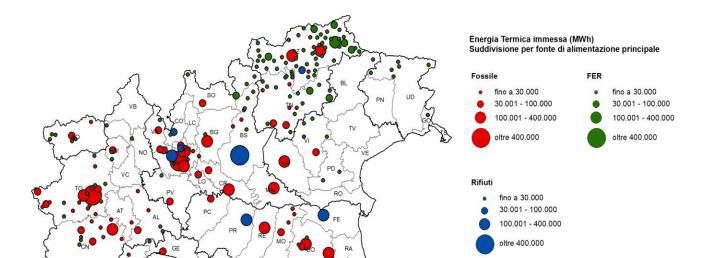

A2A Calore & Servizi’s main objective is to develop and spread the district heating service, mainly in the areas where it already exists in the municipalities of Milan, Brescia and Bergamo, adopting the best available technologies and careful management of the plants and infrastructures to safeguard the environment, save raw materials and reduce polluting emissions.

A2A has also taken part in the H2020-funded project REWARD Heat, whose objective was to demonstrate a new generation of highly efficient district heating and cooling networks, which would be able to increase production and distribution efficiency by recovering waste heat available at low temperature.

Localisation

O.R.I. Martin

Ori Martin is a steel giant. In addition to its headquarters in Brescia, it has nine other plants, some in Brescia, others in Bergamo, one in Frosinone and one in the United States. The headquarters, where the main steelworks is located, is not far from the centre of Brescia and everyday tons of scrap arrive at its plant, which is melted and then hot-rolled to produce bars, rolls, rods and long products of special steel. These products are mainly used to make metal parts for the automotive industry, from springs to bolts. From an industrial point of view, the high quality allows Ori Martin to position itself among the most advanced European producers of special steels in Europe. Current levels of production and generation of waste heat add up to about 23,000 MWh, which are sold to the city’s district heating network each year. During the winter thermal season (mid-October -mid-April) the recovered heat is transferred to the city’s district heating network; during the summer thermal season(mid-April -mid-October) the recovered heat is used to produce electricity using an ORC turbine.

The objectives

In 2016, Ori Martin, Turboden, and A2A started the iRecovery system to produce electricity and heat for the city of Brescia by recovering the heat from the steelworks that was normally wasted. iRecovery has been conceived to heat 2000 families each year (25 GW/h per year) and to produce clean electricity equivalent to the needs of 700 families, with total respect for the environment, ensuring a reduction in CO2 emissions of 10,000 tons.

The project obtained the support of the European Union Smart Cities program called PITAGORAS, acronym for Promoting Sustainable urban Planning with Innovative and low energy Thermal And power Generation frOm Residual And renewable Sources.

Key Figures

Milano

- Heat supplied : 1.2 TWh

- Heated Volume : 42.5 M m3

- Network : 317 km

- Buildings Connected : 2.800

Brescia

- Heat supplied : 1.3 TWh

- Heated Volume : 42.2 M m3

- Network : 671 km

- Buildings Connected : 21.100

Bergamo

- Heat supplied : 0.2 TWh

- Heated Volume : 6.8 M m3

- Network : 75 km

- Buildings Connected : 622

Other Areas

Cogeneration plants in Mantova, Cremona, Tirano (SO), Sellero (BS), di Sesto San Giovanni, Busto Arsizio, Cassano d’Adda, Corsico e San Donato Milanese (MI), Madesimo, Sondalo e Santa Caterina Valfurva (SO).