Austria

1997

- Type : Energy planning, Project

- Size : Regional

- Area : Residential

Environmental benefit

Heating with Woodchips in Güttenbach

Share

Austria

1997

- Type : Energy planning, Project

- Size : Regional

- Area : Residential

Environmental benefit

Discover this use case online

Concept for mobilizing unused resources from local forests:

In Güttenbach the district heating company developed a new concept for mobilizing unused resources from the local forests as energy wood. In this region there are a lot of private forest owners. Caused by the demographic change, there is an uncoordinated approach by the actors along the value chain from the forest to the energy consumption of wood. That’s why wood is unused now and there is no gain for owners or other companies.

For these reasons, a concept for improved biomass logistics has been prepared by an economic incentive for forest owners to provide forest biomass for sale as energy wood and thus to achieve a mobilization of unused forest resources. On the one hand the burden on forest owners was reduced to a minimum and on the other hand a transparent and fair billing system was introduced.

With this concept the following targets should be reached:

- Development of a local energy wood market

- Transparent marketing- and purchasing structure

- Central contact persons for procurement logistics

- Reappraise economic incentive for forest owners to thinning residues

- Mobilizing unused energy wood resources of small sized woodland owners

- Compensation of annual supply and demand fluctuation

- Prevention of polluting the lumberyard outside the forest

- Regional added value

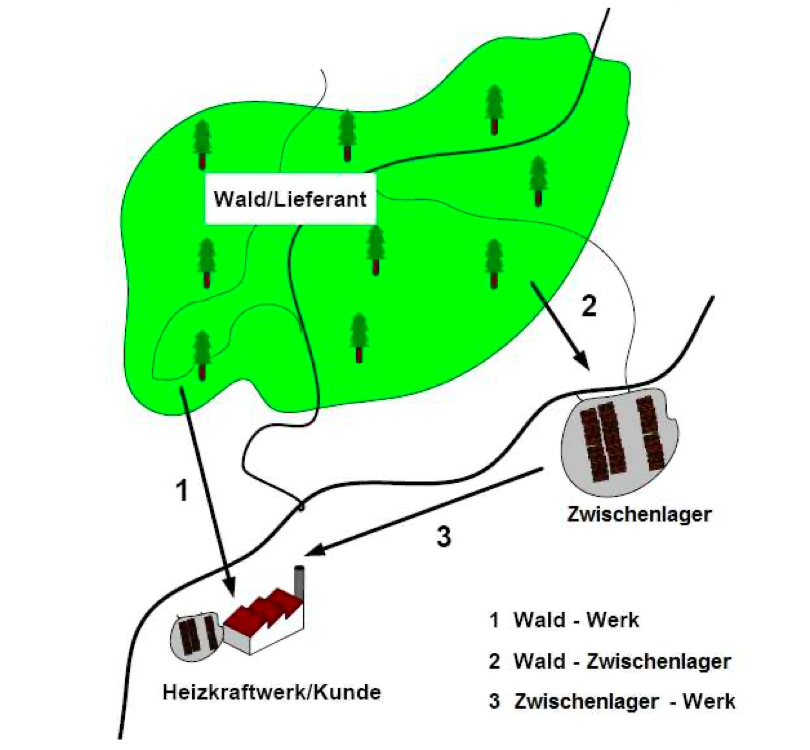

The key issue in this concept is to build smaller energy wood storage yards, where woodland owners can store and sell their wood. At the yard the energy wood is dried, chopped and stored. If there is a demand of wood chips at a power station, the wood chips are transported from the yard to the power station. In the figure above the concept is visualized. Route 1 is not adequate due to the fact that supply and demand varies significantly and the storage capacity of power plants is also limited. This fluctuation can be compensated with wood storage yards where the wood chips are stored till they are needed in the power plant.

R-ACES has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 892429

R-ACES has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 892429

Concept for mobilizing unused resources from local forests:

In Güttenbach the district heating company developed a new concept for mobilizing unused resources from the local forests as energy wood. In this region there are a lot of private forest owners. Caused by the demographic change, there is an uncoordinated approach by the actors along the value chain from the forest to the energy consumption of wood. That’s why wood is unused now and there is no gain for owners or other companies.

For these reasons, a concept for improved biomass logistics has been prepared by an economic incentive for forest owners to provide forest biomass for sale as energy wood and thus to achieve a mobilization of unused forest resources. On the one hand the burden on forest owners was reduced to a minimum and on the other hand a transparent and fair billing system was introduced.

With this concept the following targets should be reached:

- Development of a local energy wood market

- Transparent marketing- and purchasing structure

- Central contact persons for procurement logistics

- Reappraise economic incentive for forest owners to thinning residues

- Mobilizing unused energy wood resources of small sized woodland owners

- Compensation of annual supply and demand fluctuation

- Prevention of polluting the lumberyard outside the forest

- Regional added value

The key issue in this concept is to build smaller energy wood storage yards, where woodland owners can store and sell their wood. At the yard the energy wood is dried, chopped and stored. If there is a demand of wood chips at a power station, the wood chips are transported from the yard to the power station. In the figure above the concept is visualized. Route 1 is not adequate due to the fact that supply and demand varies significantly and the storage capacity of power plants is also limited. This fluctuation can be compensated with wood storage yards where the wood chips are stored till they are needed in the power plant.