Italy

- Type : Project

- Size : Local community

- Area : Industrial, Residential

Environmental benefit

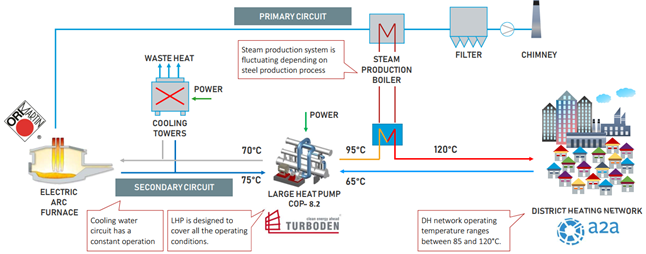

Low-Grade Waste Heat recovery in steel-making industry by coupling of Large Heat Pump and Gas Expander

Share

Italy

- Type : Project

- Size : Local community

- Area : Industrial, Residential

Environmental benefit

Discover this use case online

The feasibility of installing a Gas Expander system with power up to 1 MWe will also be studied, which will exploit the pressure jump from the gas distribution network to the plant, thus allowing ORI to produce electricity for internal self-consumption.

As a direct consequence it is estimated that the project will allow up to 5,750 emissions to be avoided into the atmosphere tons of CO2, thus combining economic advantages with environmental and social benefits.

More info

R-ACES has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 892429

R-ACES has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 892429

The feasibility of installing a Gas Expander system with power up to 1 MWe will also be studied, which will exploit the pressure jump from the gas distribution network to the plant, thus allowing ORI to produce electricity for internal self-consumption.

As a direct consequence it is estimated that the project will allow up to 5,750 emissions to be avoided into the atmosphere tons of CO2, thus combining economic advantages with environmental and social benefits.