Denmark

2021

- Type : Project

- Size : Regional

- Area : Residential

Environmental benefit

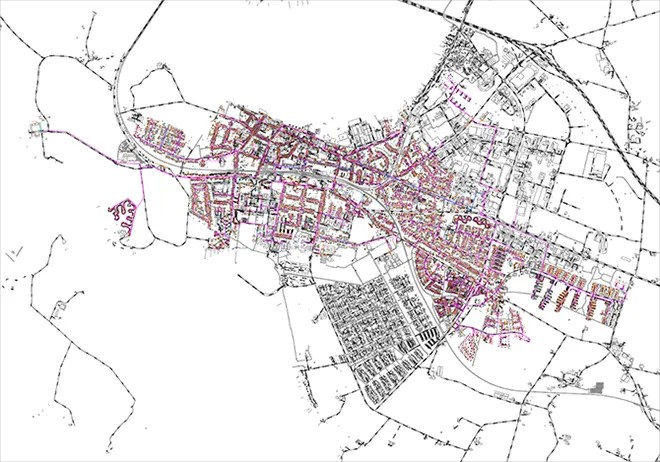

Upgrading the performance of Middelfart’s District Heating Networks

Share

Denmark

2021

- Type : Project

- Size : Regional

- Area : Residential

Environmental benefit

Discover this use case online

The District Heating system utilize industrial excess heat from TVIS as their main heat source, but they have a reserve capacity of 48 MW, that utilize natural gas or fuel oil. The spare capacity is located on their main central (Hessgade 21B), and on their second central located on Fynsvej. From the main central on Hessgade to Fynsvej, a transmission pipe transports the excess heat from TVIS.

The average MWh that are supplied by the DH network was in 2017 around 122.086 MWh. Out of 122.086 MWh, the heat production on the natural gas boilers were 28.596 MWh, equal to 23 % of the total heat production, and 94.491 MWh, equal to 77 % of the total heat production, came from the industrial excess heat.

The temperatures in the network varies throughout the year, but in average, the supply temperature is 65 degrees and return temperature is 40 degrees. The district heating network’s length is in total 148 km distributed on 75 km main pipelines and 73 km service pipes. The network consists of around 5.192 smart meters (substations) that provide information about the consumers heat demand. To optimize the current energy system they can utilize the Termis Flow Temperature Optimization (FTO), which optimizes the supply temperature at the heat plants or the TERMIS Return Temperature Optimization (RTO) model, which can give information about lowering the return temperature at specific consumers through Smart Meters, which are already installed in Middelfart DH. The heat loss in the network is around 18 %, which is a challenge for the district heating system, because it illustrates inefficiency. So lowering the heat loss must have a high priority, especially when expanding the distribution area and connecting more households to the network. These two types of software can be used to lowering the temperatures, which are key to staying competitive with e.g. individual solutions. A more long-term challenge for the DH systems in Denmark is that The Danish Government wants to be independent of fossil fuels in the energy production in 2050, meaning the utilization of natural gas must come to an end, which can cause a problem for many DH systems that utilize it as spare capacity.

R-ACES has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 892429

R-ACES has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 892429

The District Heating system utilize industrial excess heat from TVIS as their main heat source, but they have a reserve capacity of 48 MW, that utilize natural gas or fuel oil. The spare capacity is located on their main central (Hessgade 21B), and on their second central located on Fynsvej. From the main central on Hessgade to Fynsvej, a transmission pipe transports the excess heat from TVIS.

The average MWh that are supplied by the DH network was in 2017 around 122.086 MWh. Out of 122.086 MWh, the heat production on the natural gas boilers were 28.596 MWh, equal to 23 % of the total heat production, and 94.491 MWh, equal to 77 % of the total heat production, came from the industrial excess heat.

The temperatures in the network varies throughout the year, but in average, the supply temperature is 65 degrees and return temperature is 40 degrees. The district heating network’s length is in total 148 km distributed on 75 km main pipelines and 73 km service pipes. The network consists of around 5.192 smart meters (substations) that provide information about the consumers heat demand. To optimize the current energy system they can utilize the Termis Flow Temperature Optimization (FTO), which optimizes the supply temperature at the heat plants or the TERMIS Return Temperature Optimization (RTO) model, which can give information about lowering the return temperature at specific consumers through Smart Meters, which are already installed in Middelfart DH. The heat loss in the network is around 18 %, which is a challenge for the district heating system, because it illustrates inefficiency. So lowering the heat loss must have a high priority, especially when expanding the distribution area and connecting more households to the network. These two types of software can be used to lowering the temperatures, which are key to staying competitive with e.g. individual solutions. A more long-term challenge for the DH systems in Denmark is that The Danish Government wants to be independent of fossil fuels in the energy production in 2050, meaning the utilization of natural gas must come to an end, which can cause a problem for many DH systems that utilize it as spare capacity.