Denmark

2007

- Type : Project

- Size : Regional

- Area : Residential

Environmental benefit

Brædstrup district heating

Share

Denmark

2007

- Type : Project

- Size : Regional

- Area : Residential

Environmental benefit

Discover this use case online

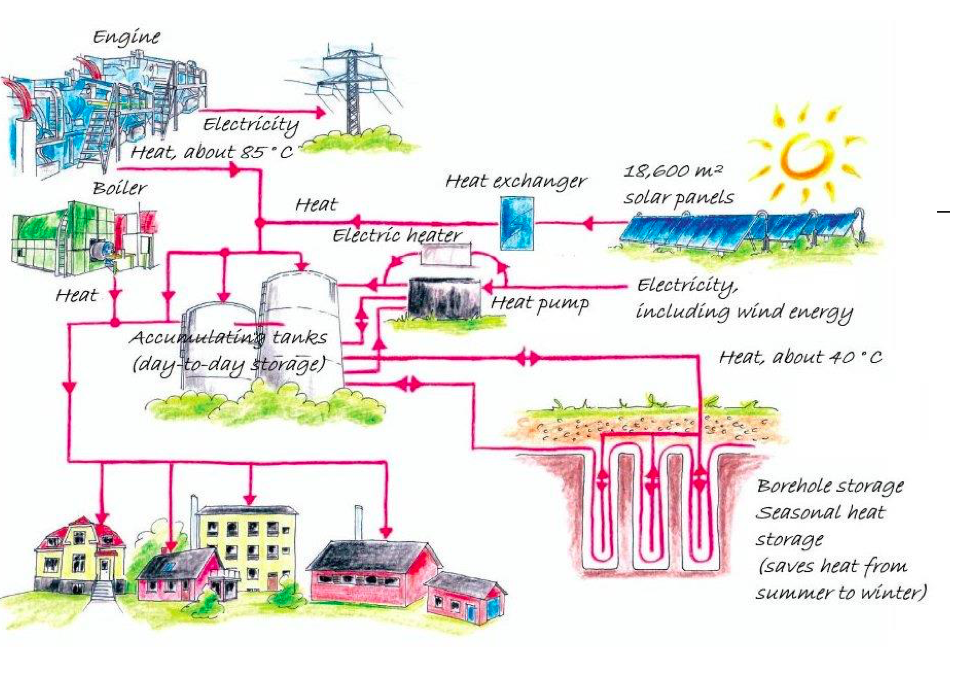

Brædstrup District Heating (DH) is a consumer owned district heating company with almost 1,500 consumers. The district heating plant started as a traditional co-generation plant including CHP and boiler units. The first step towards increasing the plants efficiency was taken in 2006 where one of the boiler units was replaced by a new unit with an efficiency of 104 %.

In 2005 no Danish natural gas fired CHP had solar district heating. Brædstrup DH made design calculations showing that solar district heating combined with CHP in an open electricity market could be a feasible solution. The electricity prices are in periods so low, that the engine is stopped and the heat production takes place on natural gas boilers, making solar district heating a feasible solution.

Based on these calculations a total of 8,000 m2 of solar collectors were commissioned in 2007. It was the world’s first solar thermal plant in combination with natural gas fired CHP. In 2008 Brædstrup DH decided to take the second step towards 100 % renewable energy (RE). It was decided to implement another 10,600 m2 of solar panels, 5,500 m2 buffer tank, 19,000 m3 pilot borehole storage, 1.2 MWth heat pump and a 10 MW electric boiler. The solar collector installation was the biggest in Europe at that time, but there is still a need for natural gas boilers as peak load.

The consumers’ benefit of the activities has been less pollution from reduction in natural gas consumption and low heat prices; Brædstrup DH is among the 25 % cheapest DH plants in Denmark. All house installations are checked every second year by the utility and all consumers can find key figures for their own consumption at Brædstrup DH ́s homepage via a personal link. All large decisions are taken by the annual general assembly, where all consumers are invited and have a vote.

A follow up project, called FlexCities, is established to continue implementing measures that contribute to 100% renewable energy. The project is a collaboration with six other district heating utilities in different municipalities. A common design study has investigated the options of using excess heat from industries, large solar thermal plants, large scale heat storages/heat pumps, biogas CHP and conversion of individually heated houses to district heating.

R-ACES has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 892429

R-ACES has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 892429

Brædstrup District Heating (DH) is a consumer owned district heating company with almost 1,500 consumers. The district heating plant started as a traditional co-generation plant including CHP and boiler units. The first step towards increasing the plants efficiency was taken in 2006 where one of the boiler units was replaced by a new unit with an efficiency of 104 %.

In 2005 no Danish natural gas fired CHP had solar district heating. Brædstrup DH made design calculations showing that solar district heating combined with CHP in an open electricity market could be a feasible solution. The electricity prices are in periods so low, that the engine is stopped and the heat production takes place on natural gas boilers, making solar district heating a feasible solution.

Based on these calculations a total of 8,000 m2 of solar collectors were commissioned in 2007. It was the world’s first solar thermal plant in combination with natural gas fired CHP. In 2008 Brædstrup DH decided to take the second step towards 100 % renewable energy (RE). It was decided to implement another 10,600 m2 of solar panels, 5,500 m2 buffer tank, 19,000 m3 pilot borehole storage, 1.2 MWth heat pump and a 10 MW electric boiler. The solar collector installation was the biggest in Europe at that time, but there is still a need for natural gas boilers as peak load.

The consumers’ benefit of the activities has been less pollution from reduction in natural gas consumption and low heat prices; Brædstrup DH is among the 25 % cheapest DH plants in Denmark. All house installations are checked every second year by the utility and all consumers can find key figures for their own consumption at Brædstrup DH ́s homepage via a personal link. All large decisions are taken by the annual general assembly, where all consumers are invited and have a vote.

A follow up project, called FlexCities, is established to continue implementing measures that contribute to 100% renewable energy. The project is a collaboration with six other district heating utilities in different municipalities. A common design study has investigated the options of using excess heat from industries, large solar thermal plants, large scale heat storages/heat pumps, biogas CHP and conversion of individually heated houses to district heating.