Denmark

2016

- Type : Project

- Size : Regional

- Area : Industrial, Residential

Environmental benefit

Gram Fjernvarme District Heating

Share

Denmark

2016

- Type : Project

- Size : Regional

- Area : Industrial, Residential

Environmental benefit

Discover this use case online

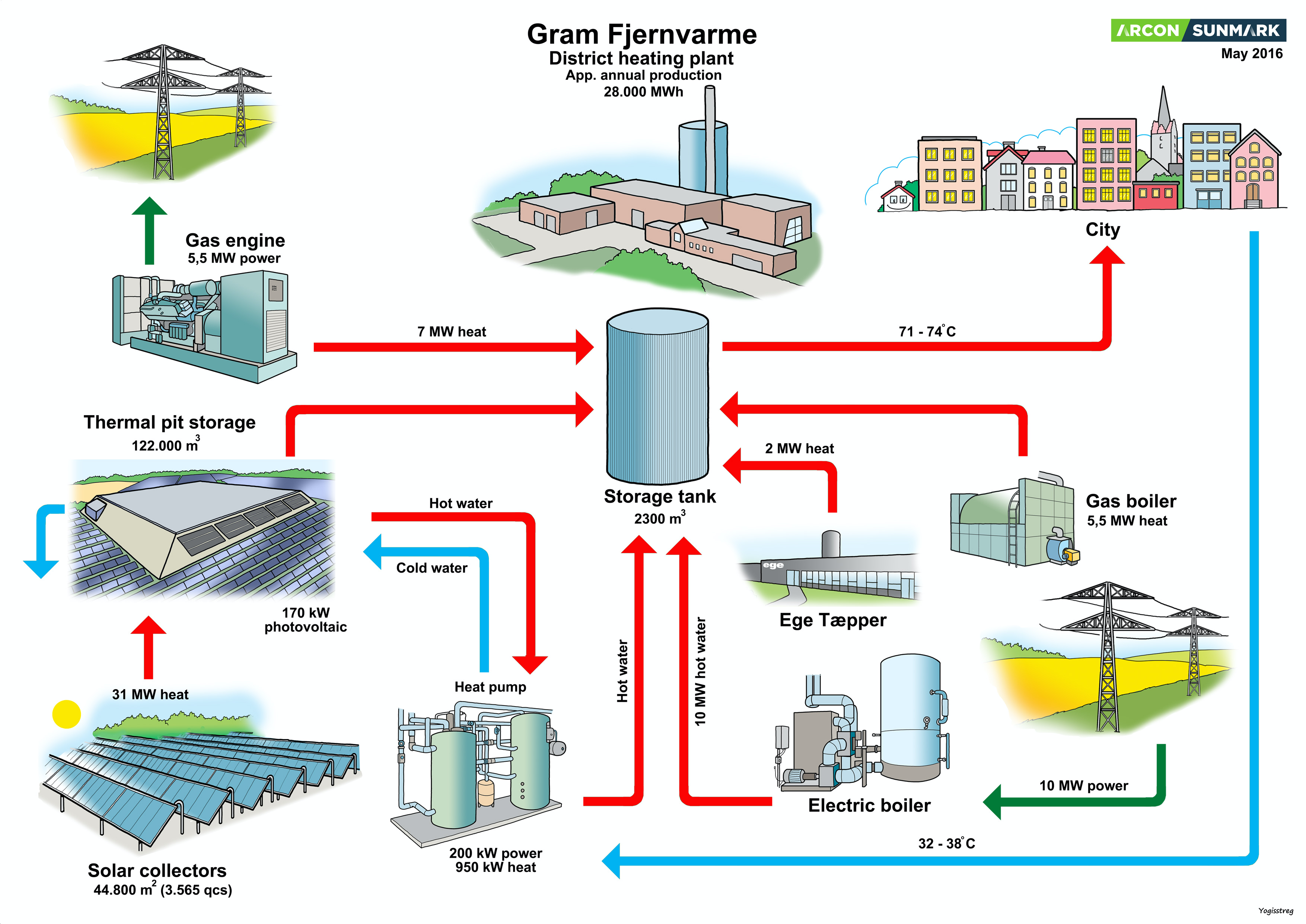

Gram District Heating Company was until 2009 based on natural gas with a CHP unit and two boilers. The heat capacity of the CHP unit is 6.5 MW and the heat capacity is 5.0 MW for each boiler. The annual heat demand is around 30,000 MWh.

The first phase of the solar field was established in 2009 and covers more than 10,000 m2 with a maximal output capacity of 6.5 MW. The solar field could cover around 15 % of the heat demand and was connected to the existing storage, a steel tank of 2,300 m3. The solar collector field is connected to the plant by a transmission line that is approximately 200 m and has a dimension DN200. The solar collector field was expanded in 2015 to have an area of 44,800 m2 in total. After the expansion the system is expected to be able to cover about 60 % of the heat production. The high penetration rate is only possible through the establishment of a seasonal pit storage, an absorption heat pump and an electric heat pump.

The purpose of the electrically-powered heat pump is to cool the bottom of the seasonal heat store. By cooling the bottom of the heat store the operating hours of the solar plant is increased and thus will be achieved by increased utilization of the solar system. The CHP unit delivers the driving energy to the absorption heat pump. This is done by replacing the high temperature flue gas heat exchanger with an approved exchanger for heated water above 150 °C. To utilize energy from the CHP unit’s exhaust gases an additional lowtemperature flue gas exchanger is implemented to cool the exhaust gas down to about 20°C. This results in an excess of cooling water that can be recovered for further optimization of gas boilers, solar heating and an electric driven heat pump. A performance of 450 – 500 kWh/m2/year is expected from the total solar system.

Gram District Heating is neighbor to a carpet factory. The carpet factory currently has two processes that have delivered surplus heat to Gram District Heating since June 2016. The surplus heat will be supplied at a temperature of 69 °C, so they only needed to establish a service line between the plant and the factory. To retrieve the excess heat 2 new heat exchangers was installed in the processes. It is expected that 2,000 MWh/year can be optained. To deliver excess heat from the factory is part of the factory´s commitment to the concept of cradle to cradle.

More info

R-ACES has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 892429

R-ACES has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 892429

Gram District Heating Company was until 2009 based on natural gas with a CHP unit and two boilers. The heat capacity of the CHP unit is 6.5 MW and the heat capacity is 5.0 MW for each boiler. The annual heat demand is around 30,000 MWh.

The first phase of the solar field was established in 2009 and covers more than 10,000 m2 with a maximal output capacity of 6.5 MW. The solar field could cover around 15 % of the heat demand and was connected to the existing storage, a steel tank of 2,300 m3. The solar collector field is connected to the plant by a transmission line that is approximately 200 m and has a dimension DN200. The solar collector field was expanded in 2015 to have an area of 44,800 m2 in total. After the expansion the system is expected to be able to cover about 60 % of the heat production. The high penetration rate is only possible through the establishment of a seasonal pit storage, an absorption heat pump and an electric heat pump.

The purpose of the electrically-powered heat pump is to cool the bottom of the seasonal heat store. By cooling the bottom of the heat store the operating hours of the solar plant is increased and thus will be achieved by increased utilization of the solar system. The CHP unit delivers the driving energy to the absorption heat pump. This is done by replacing the high temperature flue gas heat exchanger with an approved exchanger for heated water above 150 °C. To utilize energy from the CHP unit’s exhaust gases an additional lowtemperature flue gas exchanger is implemented to cool the exhaust gas down to about 20°C. This results in an excess of cooling water that can be recovered for further optimization of gas boilers, solar heating and an electric driven heat pump. A performance of 450 – 500 kWh/m2/year is expected from the total solar system.

Gram District Heating is neighbor to a carpet factory. The carpet factory currently has two processes that have delivered surplus heat to Gram District Heating since June 2016. The surplus heat will be supplied at a temperature of 69 °C, so they only needed to establish a service line between the plant and the factory. To retrieve the excess heat 2 new heat exchangers was installed in the processes. It is expected that 2,000 MWh/year can be optained. To deliver excess heat from the factory is part of the factory´s commitment to the concept of cradle to cradle.